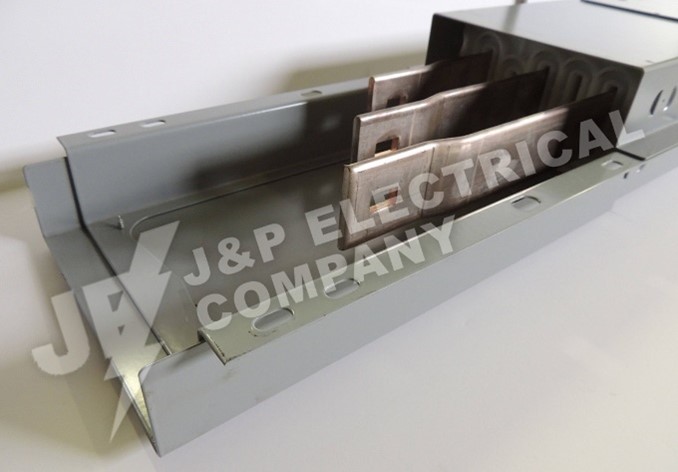

Busbars refer to metallic bars or strips which carry electrical current within electrical switchgear. These busbars are incorporated into bus ducts, a type of sheet metal duct that houses a sequence of busbars. Bus ducts offer an efficient and adaptable alternative to conventional conduits for electrical installations, simplifying the process of installation and modification.

Bus ducts are commonly used in environments where the busbars might be susceptible to damage or exposed to weather conditions. A standard bus duct system includes multiple copper or aluminum conductors, known as ‘buses’, arranged parallelly and connected to a power source.

What is Busbar Used For?

Busbars, available in several forms with distinct advantages and some limitations, are primarily used for electrical load carrying and heat dissipation. The most prevalent type is the solid busbar, which is the most cost-effective and made from a single piece of metal like copper or aluminum. In the United States, copper busbars are preferred, while aluminum is commonly used elsewhere. These busbars connect different components in electrical panels and switchgear. Due to their copper or aluminum construction, they are highly conductive and offer better resistance to corrosion.

Busbars find applications in various settings across numerous industries, including roles in:

- Electrical switchgear

- Power distribution systems

- Motor control centers

- Battery banks

- Solar panels

- Wind turbines

What is Bus Duct Used For?

Bus ducts are used primarily for the efficient distribution of electrical power in various settings, particularly in industrial and commercial buildings. Bus duct provides a high degree of electrical efficiency for both low- and high-amperage conditions. It’s also incredibly versatile, thanks to advancements such as elbows and offsets. These developments allow bus duct to adapt to directional changes.

Bus ducts are widely used in a variety of industries due to their efficiency in distributing electrical power, especially in large-scale facilities or where power requirements are substantial. Some of the key industries that commonly use bus ducts include:

- Manufacturing and Industrial Plants

- Data Centers

- Commercial Buildings

- Healthcare Facilities

- Educational Institutions

- Energy Sector

- Entertainment and Sports Venues

- Transportation Hubs

Why is Bus Duct Important for Conducting Electrical Power?

The significance of bus ducts in conducting electrical power lies in several key aspects:

- Reliability: Bus ducts ensure a steady and dependable power supply to electrical devices and systems, minimizing the likelihood of power disruptions and equipment malfunctions.

- Safety: The metal enclosure of bus ducts safeguards electrical connections and cables from damage. It also helps prevent accidental electrical contact, enhancing safety for both individuals and equipment.

- Ease of Maintenance: Designed for straightforward access, bus ducts facilitate quick repairs and component replacements, thereby reducing downtime and maintenance expenses.

- Space Efficiency: Compared to conventional cable trays, bus ducts occupy less space, making them suitable for areas with limited room.

- Flexibility: Bus ducts offer the convenience of being easily modified or extended to meet changes in electrical system requirements, thereby providing a versatile solution for various building types and equipment.

- Energy Efficiency: Bus ducts enable more effective power distribution control, which can prevent circuit overloads and lower energy consumption.

Looking for bus duct or other heavy electrical parts/equipment? We have a large 50,000 sq. feet facility with experienced and motivated staff; if we don’t have the product you are looking for, we’ll find it. When you want quality equipment at a reasonable price – fast, call J&P Electrical and we’ll get it done!

_________

J&P Electrical is a full-service electrical supply company. At J&P, we source contractors, end-users, and supply houses with new surplus, quality reconditioned, and obsolete electrical equipment. We also purchase a wide range of heavy industrial electrical equipment such as bus plugs, bus duct, transformers, circuit breakers, fuses, and switchboards. Call us at 877-844-5514 for assistance.

Written by the digital marketing team at Creative Programs & Systems: www.cpsmi.com